Understanding Auto Electrical Wire

1 – What is Auto Electrical Wire?

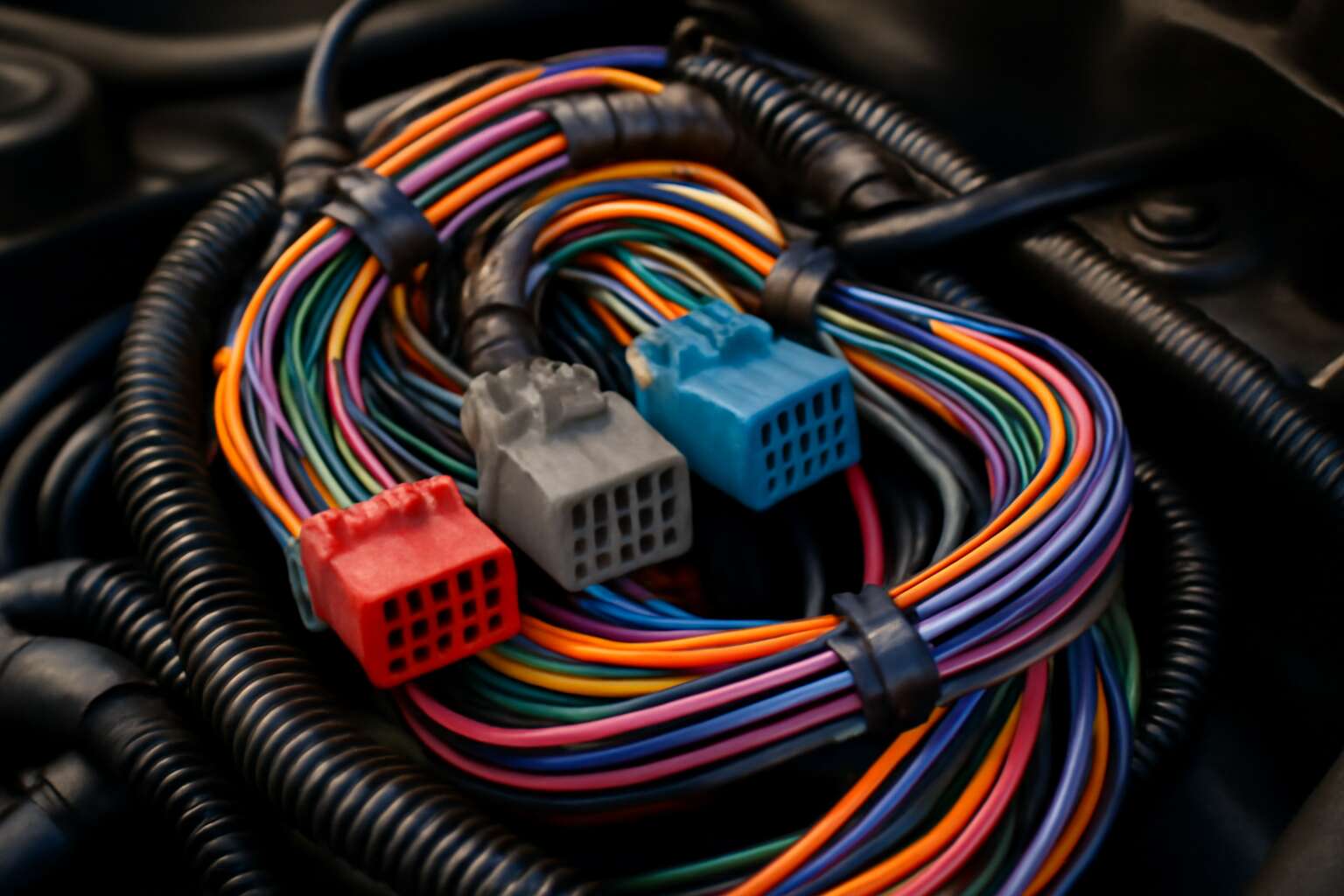

Auto electrical wire might sound like a simple component, but in reality, it’s the silent hero behind every functioning vehicle. It’s astonishing to think that a typical modern car can have over 50 metres of auto electrical wire weaving through its core, connecting everything from the ignition system to the intricate network of sensors. These wires are designed to withstand extreme temperatures, vibrations, and chemical exposure—ensuring your vehicle’s electrical system remains reliable under the most demanding conditions.

Understanding auto electrical wire begins with recognising its fundamental purpose: transmitting electrical signals and power efficiently and safely. The quality of these wires directly impacts vehicle performance and safety. They often feature specific insulation types, such as PVC or silicone, tailored to endure the rigours of automotive environments. The selection of the right auto electrical wire isn’t just about durability; it involves considering factors like current capacity, flexibility, and resistance to corrosion.

- Material composition

- Insulation quality

- Gauge size

- Temperature ratings

- Resistance to wear and tear

2 – Types of Auto Electrical Wires

Auto electrical wire is not a monolithic entity; instead, it exists in a fascinating variety that caters to the diverse demands of modern vehicles. Each type is meticulously engineered to balance flexibility, durability, and electrical capacity—crucial factors that determine the safety and performance of your vehicle’s electrical system.

Among the most common are primary wires, which serve as the backbone for power distribution, and signal wires, responsible for transmitting vital data between sensors and control units. The choice of auto electrical wire hinges on specific characteristics such as material composition and insulation quality. For instance, silicone-insulated wires excel in high-temperature environments, while PVC-insulated variants are more budget-friendly but less resistant to extreme conditions.

- High-temperature wire

- Flexible multi-core wire

- Heavy-duty power wire

Understanding these distinctions unlocks a deeper appreciation for how vital the right auto electrical wire is to both vehicle longevity and safety. Each type plays a silent but essential role in the complex choreography of your car’s electrical heartbeat.

3 – Materials Used in Auto Electrical Wiring

When it comes to auto electrical wire, choosing the right material isn’t just a matter of budget; it’s a matter of survival — especially when your vehicle’s electrical system faces the relentless onslaught of heat, vibration, and exposure to the elements. The secret lies in the composition of the wires themselves, which are crafted from materials designed to withstand the rigours of automotive life.

Many high-quality auto electrical wires are constructed with copper or aluminium conductors, both offering excellent conductivity. However, the insulation material is where the real magic happens. Silicone insulation, for example, is renowned for its exceptional temperature resistance—making it perfect for high-temperature environments like engine bays. Conversely, PVC-insulated wires are more economical and suitable for less demanding applications, but they falter under extreme conditions.

Understanding these materials is crucial because a mismatched wire can lead to failure, short circuits, or even fires. While some auto electrical wire features a multi-core design for flexibility, others are heavy-duty power wires built for high current loads.

- Silicone insulation for heat resilience

- PVC insulation for cost-effectiveness

- Multi-core configurations for flexibility

Knowing the ins and outs of these materials ensures your vehicle’s electrical system remains robust and reliable for miles to come. After all, in the world of auto electrical wire, the right choice can make all the difference between smooth sailing and electrical chaos.

4 – Common Sizes and Gauges

When it comes to auto electrical wire, size truly matters—think of it as the Goldilocks of automotive wiring: not too thick, not too thin, but just right. Different automotive applications demand specific gauges to ensure optimal performance and safety. The common sizes range from 0.5mm² for delicate signals to a hefty 16mm² for high-current feeds. Each gauge has its own personality, suited to a particular task, and choosing the wrong one can turn your vehicle into a rolling fire hazard or a sluggish mess.

To make sense of it all, here’s a quick rundown of typical auto electrical wire gauges and their ideal uses:

- 0.5mm² – Perfect for low-voltage signals, like sensors or interior lighting.

- 1.0mm² to 2.5mm² – Suitable for general lighting circuits and small accessories.

- 4mm² to 6mm² – Designed for power feeds to larger components, such as alternators or starters.

- 10mm² to 16mm² – Heavy-duty options for high current loads like main battery cables or starter motors.

Understanding these common sizes ensures your auto electrical wire matches the demands of your vehicle’s electrical system. After all, a wire that’s too thin can overheat, while one that’s too thick might be a waste of money — and space. The right gauge keeps the electrical system humming smoothly, avoiding the chaos of unexpected failures or, worse, fires that can turn a repair job into a salvage operation.

Key Features and Specifications

1 – Low Voltage vs. High Voltage Wiring

In the intricate realm of automotive innovation, understanding the distinction between low voltage and high voltage wiring is paramount. While both serve vital roles within the auto electrical wire ecosystem, their key features diverge significantly, shaping their application and safety protocols. Low voltage wiring, typically operating at 12V or 24V, is designed for sensitive electronic systems, from infotainment to sensors, ensuring delicate signals are transmitted without interference. Conversely, high voltage wiring handles the robust demands of components such as electric powertrains and lighting systems, where durability and insulation are critical.

The specifications of auto electrical wire vary according to voltage capacity, with insulation material playing a pivotal role. For high voltage applications, thicker insulation and specialised sheathing are standard, providing resistance against heat, abrasion, and electrical stress. Meanwhile, low voltage wires often feature finer gauges and flexible materials to facilitate complex routing within confined spaces. Recognising these differences ensures that each wire type performs optimally, maintaining safety and reliability across diverse automotive systems.

2 – Heat Resistance and Durability

In the high-stakes world of auto electrical wiring, heat resistance and durability aren’t just optional features; they’re non-negotiable. An auto electrical wire exposed to the relentless heat of engine compartments or the abrasive caress of road debris needs to withstand more than just a passing whim. It’s a battle of resilience, where the longevity of your wiring can mean the difference between a smooth ride and an electrical meltdown.

Reliable auto electrical wire boasts advanced insulation materials that can resist temperatures soaring well above standard operating conditions. Think of it as a thermal fortress, shielding delicate signals from the searing heat generated by exhaust systems or electrical components. Durability isn’t just about heat; it also involves resistance to corrosion, vibration, and chemical exposure. A well-designed wire will maintain its integrity, ensuring consistent performance over years of use.

For those seeking the pinnacle of resistance, many auto electrical wires feature specialised sheathing made from high-grade polymers or rubber compounds. These materials offer superior abrasion resistance and flexibility, even in cramped or twisting spaces. Remember, the best auto electrical wire combines heat resistance with mechanical robustness—because in the automotive universe, the wire’s lifespan is only as good as its toughest component.

3 – Insulation Types and Ratings

When it comes to auto electrical wire, choosing the right insulation type and rating isn’t merely a matter of preference—it’s a critical decision that can determine the longevity of your vehicle’s electrical system. Different environments demand different levels of protection, from the scorching heat of engine bays to the exposure to road salts and chemicals. An optimal auto electrical wire features insulation that not only resists high temperatures but also withstands chemical corrosion and mechanical wear.

For high-performance and safety, many auto electrical wires employ advanced insulation materials such as cross-linked polyethylene (XLPE) or thermoplastic elastomers. These materials boast impressive heat ratings—often exceeding 105°C—and are rated for specific voltage levels to ensure reliable performance. An unordered list below highlights some common insulation types and their typical ratings:

- Polyvinyl Chloride (PVC): Commonly rated for up to 70°C, suitable for general wiring.

- XLPE: Offers heat resistance up to 125°C, ideal for engine compartment wiring.

- Silicone Rubber: Superior flexibility and heat resistance, often rated for up to 200°C in specialised applications.

Understanding these ratings helps in selecting the perfect auto electrical wire for the task at hand. Whether for low-voltage signals or high-current circuits, the insulation type is the unsung hero, silently ensuring the integrity of your vehicle’s electrical system amid the chaos of daily motoring. After all, in the symphony of automotive engineering, insulation ratings are the quiet conductors maintaining harmony and safety.

4 – Flexibility and Flex Atlantic

Flexibility and resilience are the unsung heroes of auto electrical wire, often hidden behind the robustness of insulation or the gauge size. When installing wiring in confined engine bays or intricate dashboard layouts, the ability of the wire to bend without cracking or losing conductivity becomes paramount. High-quality auto electrical wire features a flexible core, often reinforced with specialised coatings, ensuring it can withstand repeated movement and vibrations without fatigue.

For demanding automotive environments, the flexibility of auto electrical wire is complemented by its mechanical durability. This combination guarantees that even in the most dynamic settings—where wires twist, turn, and flex—performance remains unimpaired. Some wires incorporate a flexible “flex Atlantic” coating, designed specifically to enhance bendability while maintaining electrical integrity under extreme conditions.

In practice, selecting auto electrical wire with superior flexibility isn’t just about ease of installation; it’s about long-term reliability. Whether routing under the chassis or through tight engine compartments, choosing a wire that merges flexibility with durability ensures your vehicle’s electrical system remains intact, silent, and efficient in the face of daily automotive chaos.

Applications of Auto Electrical Wire

1 – Wiring for Lighting Systems

Lighting systems are vital to vehicle safety and aesthetics. Auto electrical wire plays a crucial role in ensuring these systems function flawlessly. From headlights to interior ambient lighting, the correct wiring guarantees reliable power delivery and longevity. High-quality auto electrical wire is designed to withstand vibrations, temperature fluctuations, and exposure to elements, making it ideal for automotive environments.

In modern vehicles, lighting applications demand specialised wiring solutions. For example, LED lighting systems require wires with specific insulation ratings to prevent shorts and ensure efficient operation. Using the right auto electrical wire not only enhances performance but also reduces the risk of electrical faults.

Some automotive manufacturers prefer a combination of different wire gauges and insulation types to optimise lighting system performance. This tailored approach ensures that each component receives the appropriate level of power and protection, ultimately improving vehicle safety and driver visibility.

2 – Battery and Charging System Wiring

In the realm of automotive power management, the battery and charging system rely heavily on specialised auto electrical wire to ensure seamless operation. These wires serve as the vital arteries that deliver the necessary current to start the engine, power accessories, and maintain battery health. Without robust wiring, even the most sophisticated charging systems risk failure, leaving drivers stranded in moments of need.

Auto electrical wire used in these critical applications must withstand high current loads and fluctuating voltages. Material quality, insulation ratings, and gauge size all play pivotal roles in ensuring safety and longevity. For instance, thicker gauges of auto electrical wire are often employed for main power feeds, while thinner wires may be reserved for sensor signals or control circuits. This deliberate differentiation ensures each component receives optimised power, reducing the risk of electrical faults that could impair vehicle performance.

- High-quality auto electrical wire with excellent conductivity ensures minimal power loss during transmission.

- Specialised insulation safeguards against heat, vibrations, and moisture—common foes in automotive environments.

- Flexible auto electrical wire facilitates easier routing through tight engine bays, reducing installation complexity.

3 – Audio and Multimedia Systems

In the realm of automotive audio and multimedia systems, the role of auto electrical wire is often underestimated—until, that is, your favourite playlist cuts out mid-chorus or your personalised dashboard lighting flickers into obscurity. These wires serve as the unsung heroes behind crystal-clear sound and seamless connectivity, ensuring your in-car entertainment remains uninterrupted. From powering high-end speakers to connecting complex multimedia modules, specialised auto electrical wire guarantees a reliable conduit for data and power alike.

High-quality auto electrical wire dedicated to audio systems must deliver superb conductivity while resisting the rigours of vibrations and temperature fluctuations. Employing thicker gauges for main power feeds ensures stable voltage delivery, while finer wires handle delicate signal transmission. The insulation on these wires is tailored to prevent interference—an essential feature in ensuring audio fidelity and system longevity. Whether routing through tight engine bays or discreetly tucked behind panels, flexible auto electrical wire facilitates installation and reduces the risk of future faults.

4 – Engine Control and Sensor Wiring

Engine control and sensor wiring form the backbone of modern vehicle diagnostics and performance optimisation. Reliable auto electrical wire ensures that sensors—such as oxygen sensors, temperature sensors, and pressure sensors—transmit accurate data to the vehicle’s ECU (Electronic Control Unit). This data is vital for adjusting fuel delivery, ignition timing, and emissions control, ultimately affecting the vehicle’s efficiency and compliance with environmental standards.

In complex engine systems, the integrity of auto electrical wire becomes even more critical. Poor quality wiring can lead to inconsistent signals, causing misfires, sluggish response times, or even engine failure. For these reasons, specialised auto electrical wire used in engine control wiring often features high durability, resistance to heat, and excellent insulation properties to withstand the extreme conditions found under the bonnet.

When installing or repairing engine wiring, it’s essential to consider the application-specific requirements. For example, sensor wires are typically finer and more flexible, allowing them to navigate tight spaces without damage. Meanwhile, main power feeds require thicker gauges to handle higher currents efficiently.

- Temperature-resistant insulation

- Vibration-proof design

- Corrosion-resistant materials

all contribute to enhancing the longevity of auto electrical wire in demanding engine environments.

Installation and Maintenance Tips

1 – Proper Wiring Techniques

In the realm of auto electrical wire installation, precision is paramount. Every strand must be laid with deliberate care, for a single misstep can compromise the entire electrical system. Proper wiring techniques not only ensure safety but also extend the lifespan of components, transforming a mundane task into a testament of craftsmanship. When working with auto electrical wire, it’s essential to maintain a clean, organised workspace, free from tangled cables and stray debris that can cause shorts or corrosion.

To achieve impeccable results, adhere to established standards that promote seamless connectivity. Use appropriate connectors and ensure tight, corrosion-resistant joints. For added durability, consider employing heat-shrink tubing and protective sheathing, which shield the auto electrical wire from environmental stresses. Here are some foundational steps to elevate your wiring craftsmanship:

- Plan your wiring routes meticulously, avoiding sharp edges and heat sources.

- Strip insulation carefully, exposing just enough conductor without damaging the wire.

- Secure wires with quality clips and cable ties, preventing movement that could lead to wear over time.

By embracing these proper wiring techniques, professionals and enthusiasts alike can craft a reliable, safe, and efficient electrical system—one that honours the elegance of automotive engineering while safeguarding its future. The artistry lies not only in the wire itself but in the meticulous attention to detail that transforms ordinary auto electrical wire into a masterpiece of functional design.

2 – Common Troubleshooting Issues

Once the delicate dance of wiring is complete, the journey of installation and maintenance begins—an ongoing symphony that ensures your auto electrical wire system remains resilient against time’s relentless march. Troubleshooting common issues can feel like deciphering an ancient script; flickering lights, sluggish performance, or inexplicable faults often whisper secrets of underlying wiring dilemmas. Recognising these signals early can prevent minor glitches from blossoming into costly repairs, preserving the harmony of your vehicle’s electrical symphony.

Regular inspection of auto electrical wire connections is paramount. Loose or corroded joints are frequent culprits of electrical failures. Employing a multimeter to trace voltage drops along the wiring can reveal hidden weaknesses, guiding precise repairs. When issues arise, consider inspecting the insulation integrity — damaged auto electrical wire insulations expose conductors to moisture and debris, risking shorts and corrosion. Maintaining a clean, organised workspace and employing protective sheathing and heat-shrink tubing can prolong the life of your wiring, shielding it from environmental stresses and mechanical wear.

In the realm of troubleshooting, embracing a methodical approach often involves a simple yet effective numbered sequence:

- Identify the fault symptom and isolate the affected circuit.

- Check for physical damage or corrosion at connection points.

- Test continuity of the auto electrical wire using appropriate tools.

- Replace damaged sections with high-quality wiring and ensure secure connections.

By nurturing your auto electrical wire with attentive care and understanding, you weave a tapestry of reliability that not only powers your vehicle but elevates its artistry to a realm where craftsmanship meets ingenuity. The secret lies in patience, precision, and a deep respect for the silent threads that animate your automotive masterpiece.

3 – Safety Guidelines for Auto Wiring

Safety in auto electrical wiring is paramount; a single lapse can turn a meticulously crafted system into a perilous hazard. Every technician or enthusiast must adhere to strict safety guidelines to protect themselves and ensure vehicle integrity. Properly disconnect the battery before beginning any wiring work—this simple step is the first line of defence against accidental shorts or shocks. Additionally, wearing insulated gloves and eye protection can prevent injuries from unforeseen sparks or wire fragments.

Maintaining a secure workspace is equally important. Keep your auto electrical wire organised, away from moisture, and free from mechanical stress that could compromise insulation integrity. When connecting wires, ensure all joints are solid and insulated with high-quality sheathing or heat-shrink tubing. Remember, a well-maintained wiring system not only safeguards your vehicle but also prolongs the lifespan of your auto electrical wire, ultimately preserving the harmony of your vehicle’s electrical symphony.

4 – Replacing and Upgrading Auto Wires

Replacing and upgrading auto electrical wire is akin to restoring the heartbeat of a vehicle’s electrical symphony. When the time comes to refresh old wiring or enhance your system’s capabilities, meticulous attention to detail ensures longevity and safety. Begin by carefully inspecting existing wiring for signs of wear, fraying, or corrosion—these subtle indicators often foreshadow larger issues. Selecting the appropriate auto electrical wire, with regard to gauge and insulation type, is crucial for maintaining optimal performance. Remember, the right wire not only handles current efficiently but also withstands the demands of your vehicle’s environment.

For seamless upgrades, consider organising your work with a numbered approach:

- Disconnect the battery and isolate the circuit.

- Remove the old auto electrical wire with care, avoiding damage to surrounding components.

- Lay out the new wiring, ensuring it matches the original routing to prevent mechanical stress.

- Secure connections with high-quality sheathing or heat-shrink tubing to guarantee insulation integrity.

To prolong the lifespan of your auto electrical wire, regular maintenance is essential. Routinely check for any signs of deterioration, especially in areas exposed to moisture or extreme temperatures. Ensuring that all connections are tight and free from corrosion preserves conductivity and prevents voltage drops. Proper installation and diligent upkeep of auto electrical wire ultimately safeguard your vehicle’s electrical ecosystem, keeping it vibrant and responsive for miles to come.

Choosing Quality Auto Electrical Wire Supplier

1 – Criteria for Selecting Auto Wiring Brands

Choosing a reliable auto electrical wire supplier is akin to selecting the guardian of your vehicle’s heartbeat. The quality of the auto electrical wire used in your automotive systems directly influences performance, safety, and longevity. A trusted supplier doesn’t just offer products—they provide assurance that every strand of wire meets rigorous standards of durability and efficiency.

When sourcing auto electrical wire, consider the supplier’s reputation and their adherence to industry certifications. It’s vital that the **auto electrical wire** they provide is crafted from premium materials that withstand the rigours of daily driving and extreme weather conditions. Look for brands renowned for consistency in quality and transparency in their manufacturing processes—these attributes are the backbone of a successful partnership.

Furthermore, evaluate their range of offerings, ensuring they cater to the specialised needs of different automotive systems. Whether you require wiring for high-voltage applications or specialised insulation ratings, a reputable supplier will have a broad selection of auto electrical wire to meet diverse requirements.

2 – Certifications and Standards

In the realm of automotive mastery, selecting a supplier of **auto electrical wire** fortified with proper certifications is akin to choosing a legendary smith for your chariot’s heart. Certifications act as a mystical seal of quality, ensuring that each strand of wire adheres to rigorous standards that transcend mere craftsmanship—these are the scrolls of industry validation. When a supplier boasts certifications such as ISO 9001 or ISO/TS 16949, it signals unwavering commitment to excellence, durability, and safety.

To truly unveil the calibre of your **auto electrical wire** provider, delve into their adherence to standards like the SAE J1128 or the UL certification. These benchmarks serve as the armour of trust, safeguarding your vehicle’s electrical symphony against the chaos of the road. A supplier with a transparent manufacturing process and recognised standards becomes not just a provider but a guardian of your vehicle’s longevity and performance. Such standards are the lodestone guiding you towards a partnership that ensures each wire strand is imbued with resilience and efficiency, ready to withstand the tempest of daily driving.

3 – Price vs. Quality Considerations

When weighing the cost of auto electrical wire, many are tempted to choose the cheapest option available. However, in the world of automotive wiring, saving a few pounds upfront can lead to costly repairs down the line. High-quality auto electrical wire isn’t just about affordability; it’s an investment in durability and safety. Opting for inferior wiring may seem budget-friendly initially, but it often results in frequent failures, increased maintenance, and potential safety hazards.

To navigate this delicate balance between price and quality, consider the following:

- Assess the supplier’s reputation and adherence to recognised standards.

- Compare material specifications, especially insulation and conductor quality.

- Prioritise certifications like ISO 9001 and UL, which ensure rigorous quality controls.

Remember, the finest auto electrical wire will serve as the backbone of your vehicle’s electrical system, ensuring reliable performance under the harshest conditions. While it might cost a little more, the peace of mind and longevity it provides are priceless. In this realm, quality should always triumph over mere cost—your vehicle’s future depends on it!

4 – Where to Buy Auto Electrical Wires

Finding a reliable source for auto electrical wire is not merely a matter of convenience; it’s an act of safeguarding your vehicle’s very essence. The truth is, where you purchase your auto electrical wire influences its quality, durability, and ultimately, your safety on the road. A reputable supplier doesn’t just offer product; they provide assurance that every metre of wiring meets stringent standards and withstands the relentless test of time and environment.

When selecting a supplier, consider their reputation within the industry. Do they adhere to recognised standards like ISO 9001 or UL? These certifications are more than formalities—they are guarantees of quality control and rigorous testing. Opting for trusted brands or specialised auto electrical wire suppliers often means you’re investing in longevity and safety rather than short-term savings.

In addition, seek out suppliers who offer a comprehensive range of auto electrical wire types, ensuring compatibility with your specific vehicle needs. Whether you require wiring for complex multimedia systems or critical engine sensors, the right supplier will facilitate your journey with expert guidance and quality assurance. After all, in the realm of auto electrical wiring, the choice of where to buy is as crucial as the wire itself—because every connection matters.

0 Comments